•Microprocessor controlled

•Shell & tube type evaporator

•Hydronic kit optional

Usage areas;

•Air-conditioning systems

•Process cooling

•Plastic,chemical,food,textile industries

•For different purposes

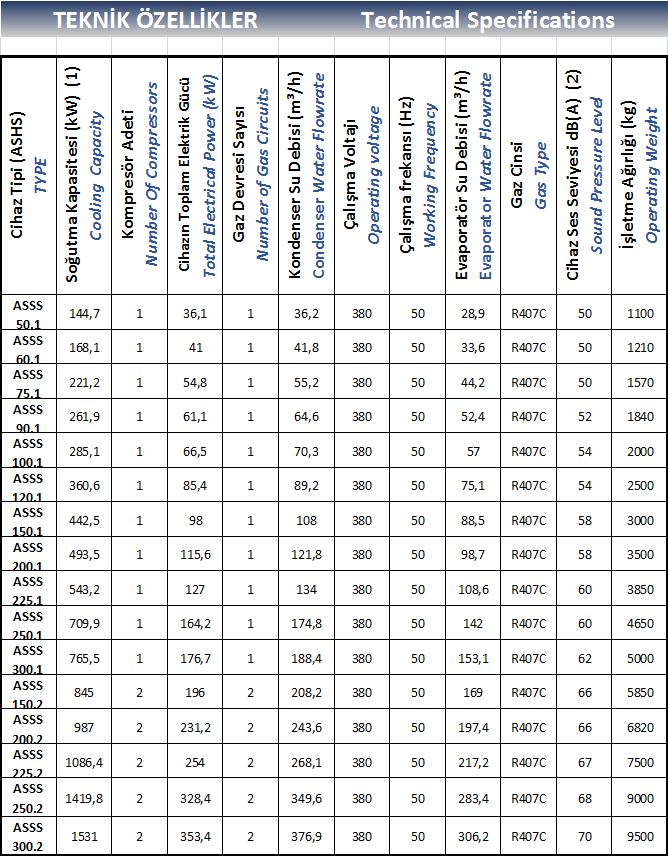

The cooling capacities of compact units in our plant range from 73,5 kW to 738 kW.

1,2 or 4 semi-hermetic reciprocating compressors are used according to the capacity.It can work according to all gases. Easy to maintain and long lasting.

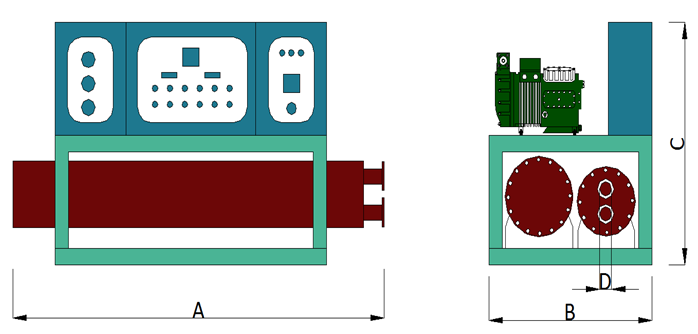

Condenser:

Shell&tube type producing, a special high-efficiency copper tubing with steel mirror is determined to holes by tube expander. Copper pipes are specially treated to increase heat transfer. Special cleaning tools are available in the future.

Evaporator:

Shell&tube type producing, a special high-efficiency copper tubing with steel mirror is determined to holes by tube expander. The outer body is insulated with special rubber insulation.

Electrical Control Panel:

Control of the system is carried out through this board.It is equipped with suitable capacity and number of switches, contactors, thermal, fuse, switch and similar electric shafts for fully automatic operation of the system.

Cooling Circuit Elements:

Dryer, sight glass, electronic expansion valve, solenoid valve, pressure proceses, flow-switch, cooling valves, water and air discharge valves are used for proper operation of the system.

Microprocessor Control Unit:

The microprocessor control unit controls the water inlet and outlet temperature values and possible fault conditions in the system. In addition, the operating hours of the compressors are automatically compensated.